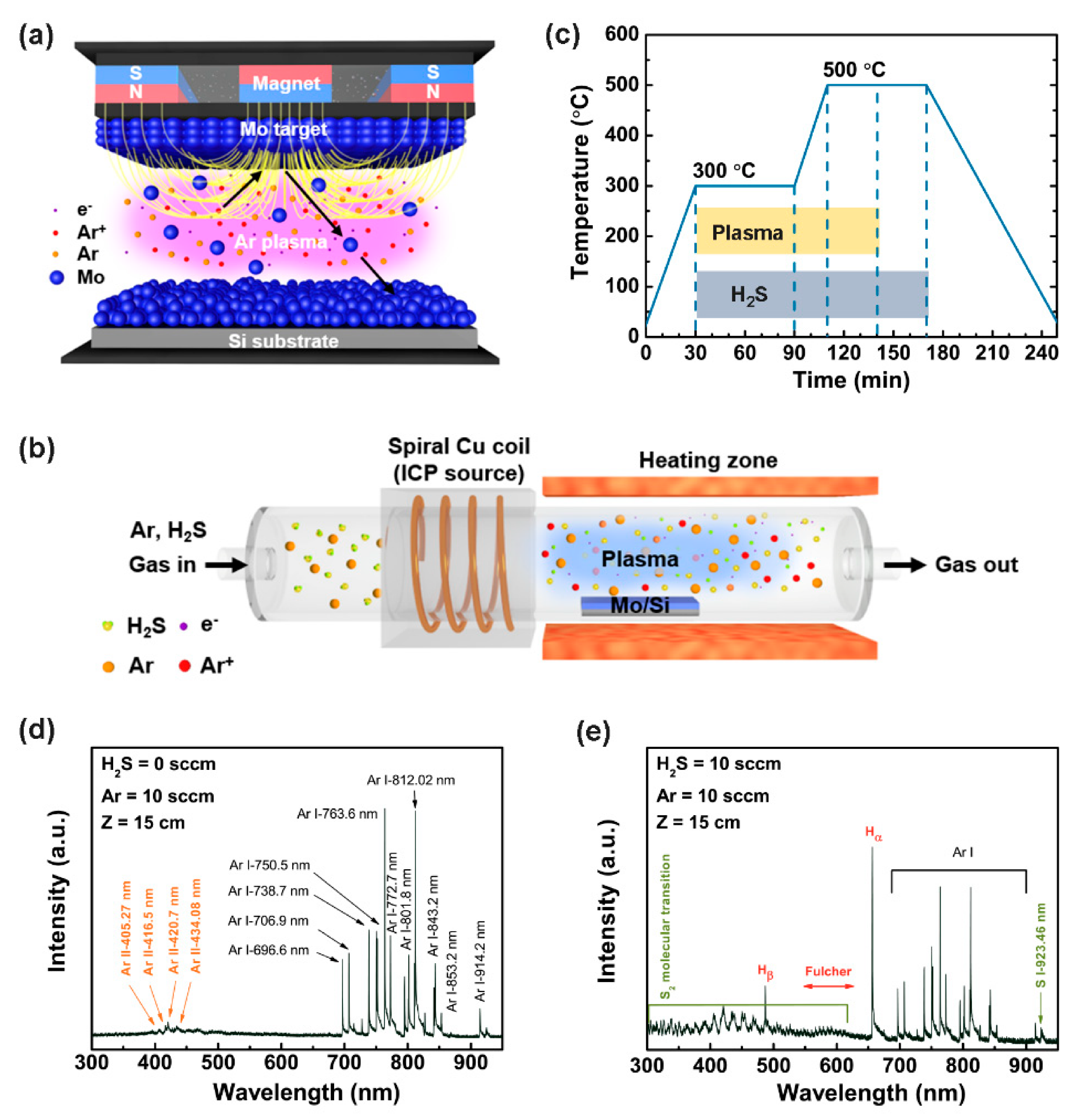

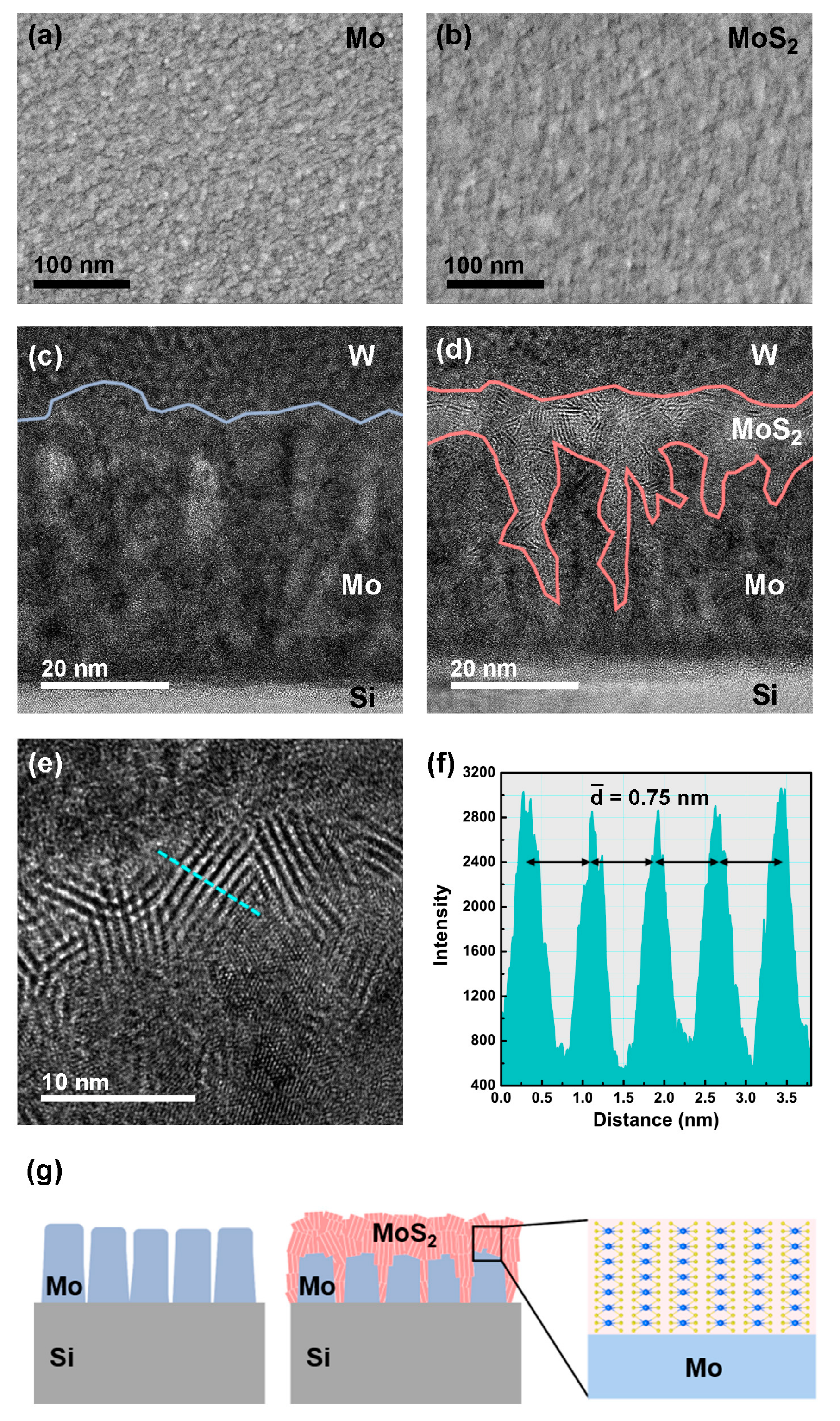

The act of applying a thin film to a surface is thin film deposition any technique for depositing a thin film of material onto a substrate or onto previously deposited layers.

Exotic energy deposition in ceramics.

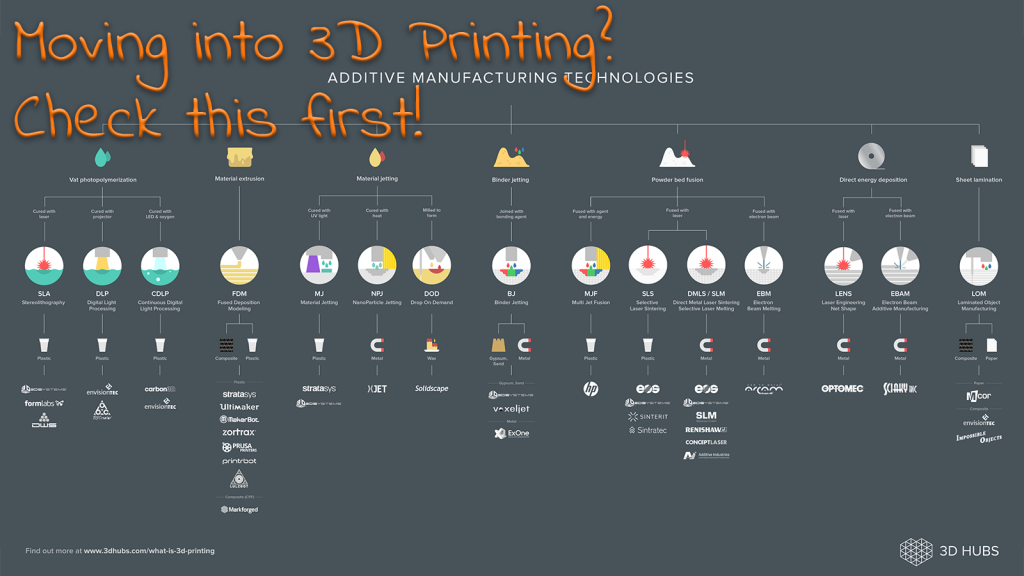

Search our database of additive manufacturing suppliers including 3d printer manufacturers material providers software developers auxiliary equipment manufacturers service bureaus and more.

André anders in handbook of deposition technologies for films and coatings third edition 2010.

Molecular beam epitaxy the langmuir blodgett method atomic layer deposition and.

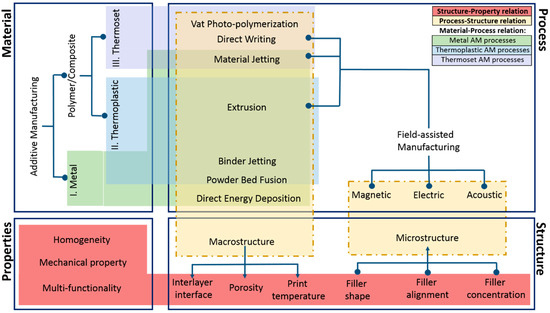

Directed energy deposition ded is a kind of additive manufacturing am technology based on synchronous powder feeding or wire feeding.

The temperature and transit time are adjusted so as to accomplish rapid evaporation and oxidation.

Exotic energy deposition methods also are used in the sintering of advanced ceramics.

An intense laser pulse is focused onto.

The result is a high purity powder with fine particle size.

Advanced ceramics have stages mentioned above.

Thin is a relative term but most deposition techniques control layer thickness within a few tens of nanometres.

This paper aims to provide a review on the process of additive manufacturing of ceramic materials focusing on partial and full melting of ceramic powder by a high energy laser beam without the use of binders selective laser sintering or melting sls slm techniques are first introduced followed by analysis of results from silica sio2 zirconia zro2 and ceramic reinforced metal matrix.

It has been classified into numerous products including electro magnet optical and thermodynamical applications.

Cathodic arc deposition is a technique that can produce diamond like amorphous carbon films with very high sp 3 content such that they are sometimes called amorphous diamond films 218 220 for most applications of such films the incorporation of.

Spray roasting involves spray atomization of solutions of water soluble salts into a heated chamber.

Pulsed laser deposition chrisey and hubler 1994.

One reason is that conventional radiant heating is slow so that ceramic powders lose much of their activity or sinterability during heat up.

Directed energy deposition ded is a kind of additive manufacturing am technology based on synchronous powder feeding or wire feeding.

A modification of spray roasting known as rapid thermal decomposition of.

10 7 1 tetrahedral amorphous carbon.

It is therefore advantageous to heat ceramics to the sintering temperature as rapidly as possible.